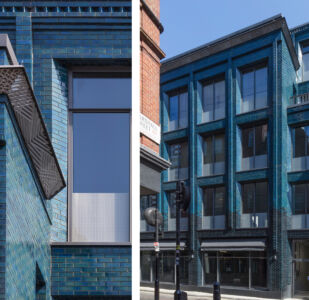

The decorative brick facades of Stiff & Trevillion’s 40 Beak Street in London’s Soho are intended to respond to the rich architectural history of the district. The building, conceived by developers Enstar Capital and Landcap, has been acquired by artist Damien Hirst for use as a flagship studio and art complex. “Beak Street forms part of a network of narrow streets dating back to the late seventeenth century, and the majority of the buildings are historic, individualistic and constructed in brick”, says the architect. “Early in the design process we envisaged a heavyweight building with depth and texture; brick was the obvious choice for the facade.”

Once the basic fenestration arrangement had been established, Stiff & Trevillion “began to develop various details to enhance the design”. These included projecting piers to accentuate the verticals and conceal movement joints, and splayed window reveals intended to improve visibility from within the building and to increase daylight penetration.

Given the amount of repetition in the facade, Stiff & Trevillion initially anticipated that it would be constructed using precast modules clad with glazed brick slips, and worked with a specialist in hand-glazing to develop samples. However, the target costs proved difficult to achieve, so instead, the design was revised to incorporate hand-laid whole bricks, of which more than 100 special brick formats were required. “We originally hoped that the brickwork could be loadbearing”, says the architect, “but site logistics required that the ground floor facade was completed towards the end of the project, and this meant that the brickwork was instead supported on stainless steel angles fixed back to the concrete structure”.

The facade, enlivened with commissioned art by Lee Simmons, was constructed with the brick acting as a rainscreen, using secondary steel framing as the inner leaf, faced in cementitious board. This meant that the building could be made watertight quickly, with the brickwork taken off the critical path and progressed in parallel with the internal works. Aluminium windows were fitted to apertures in the steel framing system, carefully set out to brick modules, and fully sealed to the breather membrane with the EPDM mechanically fixed to all sides of the window. Black mortar was used, with 7mm joints. Combined with ‘T’ and ‘L’ profile caps to the glazing, this “helped to give definition to the facade, and a precise, elegant appearance”, says Stiff & Trevillion.